Eddy current separator is also named eddy current non ferrous metal separator, it is specially used to recycle nonferrous metals such as copper and aluminum from industrial waste and domestic garbage.

Widely used for household waste, industrial waste, industrial waste slag, electronic appliances waste, glass broken materials, boiler ashes, scrap car slice, such as copper, aluminum, tin, lead, stainless steel and other kinds of weak magnetic conductor materials, non-magnetic conductor materials, non-ferrous metals and other materials in the industry of non-ferrous metals processing.

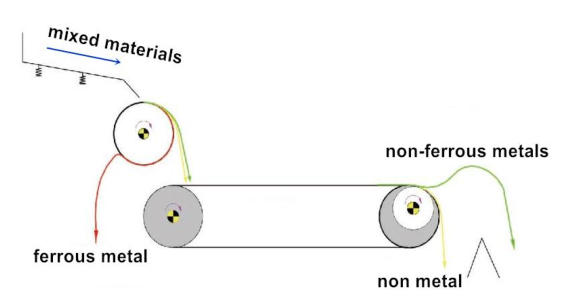

When the machine is working , alternating magnetic field created on the magnetic roller surface. When the non-ferrous metal across the magnetic field, Eddy current appear in the non-ferrous metal. Eddy current in the non-ferrous metal create magnetic field which is opposite to the magnetic field in the separator, in this way, the mixed material is separated. This machine is high recycling rate . An Eddy Current Separator consists of a short belt conveyor that has its drive located at the return end and a high speed magnetic rotor system installed at the discharge end.As the rotor spins at these high speeds, an electric current is induced into conducting metals. The induced current produces a magnetic field that opposes the magnetic field generated by the rotor and repels the conductive metal on the pre-positioned separation plate. The remaining materials, such as plastic, glass and other dry recyclable materials, will simply fall freely on the rotor, separating them from the ejected metal.

1. No need for any fuel in the whole process.

2. To reduce the dirt, smog pollution problem with dirt and smoke ventilation equipment.

3. Automatic mechanical operation, no harmful to the operator’s health.

4. High efficiency for recycling rate.

Model | Magnetic drum speed(r/min) | Belt width (mm) | Main unit power (kw) | Feeder power (kw) |

ECS-400 | 0-3000 | 450 | 3.0+0.55 | 0.25*2 |

ECS -600 | 0-3000 | 650 | 4.0+0.75 | 0.25*2 |

ECS-800 | 0-3000 | 800 | 5.5+1.1 | 0.55*2 |

ECS -1200 | 0-3000 | 1200 | 7.5+1.1 | 0.75*2 |

ECS -1500 | 0-3000 | 1500 | 11+3.0 | 0.75*2 |